Hello, in this particular article you will provide several interesting pictures of what is the reactor used to make. We found many exciting and extraordinary what is the reactor used to make pictures that can be tips, input and information intended for you. In addition to be able to the what is the reactor used to make main picture, we also collect some other related images. Find typically the latest and best what is the reactor used to make images here that many of us get selected from plenty of other images.

.jpg) We all hope you can get actually looking for concerning what is the reactor used to make here. There is usually a large selection involving interesting image ideas that will can provide information in order to you. You can get the pictures here regarding free and save these people to be used because reference material or employed as collection images with regard to personal use. Our imaginative team provides large dimensions images with high image resolution or HD.

We all hope you can get actually looking for concerning what is the reactor used to make here. There is usually a large selection involving interesting image ideas that will can provide information in order to you. You can get the pictures here regarding free and save these people to be used because reference material or employed as collection images with regard to personal use. Our imaginative team provides large dimensions images with high image resolution or HD.

what is the reactor used to make - To discover the image more plainly in this article, you are able to click on the preferred image to look at the photo in its original sizing or in full. A person can also see the what is the reactor used to make image gallery that we all get prepared to locate the image you are interested in.

what is the reactor used to make - To discover the image more plainly in this article, you are able to click on the preferred image to look at the photo in its original sizing or in full. A person can also see the what is the reactor used to make image gallery that we all get prepared to locate the image you are interested in.

We all provide many pictures associated with what is the reactor used to make because our site is targeted on articles or articles relevant to what is the reactor used to make. Please check out our latest article upon the side if a person don't get the what is the reactor used to make picture you are looking regarding. There are various keywords related in order to and relevant to what is the reactor used to make below that you can surf our main page or even homepage.

We all provide many pictures associated with what is the reactor used to make because our site is targeted on articles or articles relevant to what is the reactor used to make. Please check out our latest article upon the side if a person don't get the what is the reactor used to make picture you are looking regarding. There are various keywords related in order to and relevant to what is the reactor used to make below that you can surf our main page or even homepage.

Hopefully you discover the image you happen to be looking for and all of us hope you want the what is the reactor used to make images which can be here, therefore that maybe they may be a great inspiration or ideas throughout the future.

Hopefully you discover the image you happen to be looking for and all of us hope you want the what is the reactor used to make images which can be here, therefore that maybe they may be a great inspiration or ideas throughout the future.

All what is the reactor used to make images that we provide in this article are usually sourced from the net, so if you get images with copyright concerns, please send your record on the contact webpage. Likewise with problematic or perhaps damaged image links or perhaps images that don't seem, then you could report this also. We certainly have provided a type for you to fill in.

All what is the reactor used to make images that we provide in this article are usually sourced from the net, so if you get images with copyright concerns, please send your record on the contact webpage. Likewise with problematic or perhaps damaged image links or perhaps images that don't seem, then you could report this also. We certainly have provided a type for you to fill in.

The pictures related to be able to what is the reactor used to make in the following paragraphs, hopefully they will can be useful and will increase your knowledge. Appreciate you for making the effort to be able to visit our website and even read our articles. Cya ~.

The pictures related to be able to what is the reactor used to make in the following paragraphs, hopefully they will can be useful and will increase your knowledge. Appreciate you for making the effort to be able to visit our website and even read our articles. Cya ~.

Tubular Reactor: The Ultimate FAQ Guide - Filson Filter

Tubular Reactor: The Ultimate FAQ Guide - Filson Filter

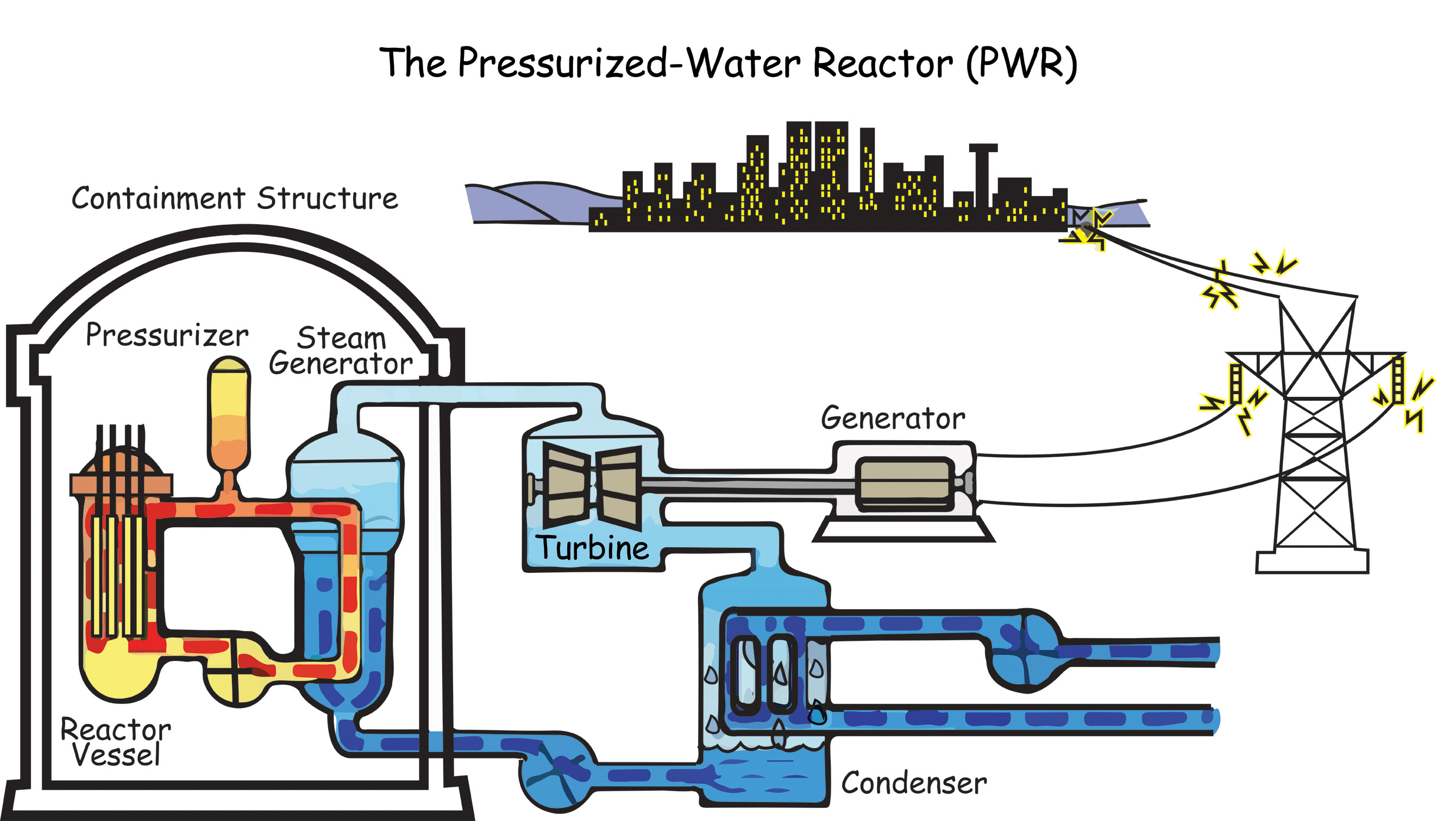

74: Generating Electricity by Using Fission - Chemistry LibreTexts

74: Generating Electricity by Using Fission - Chemistry LibreTexts

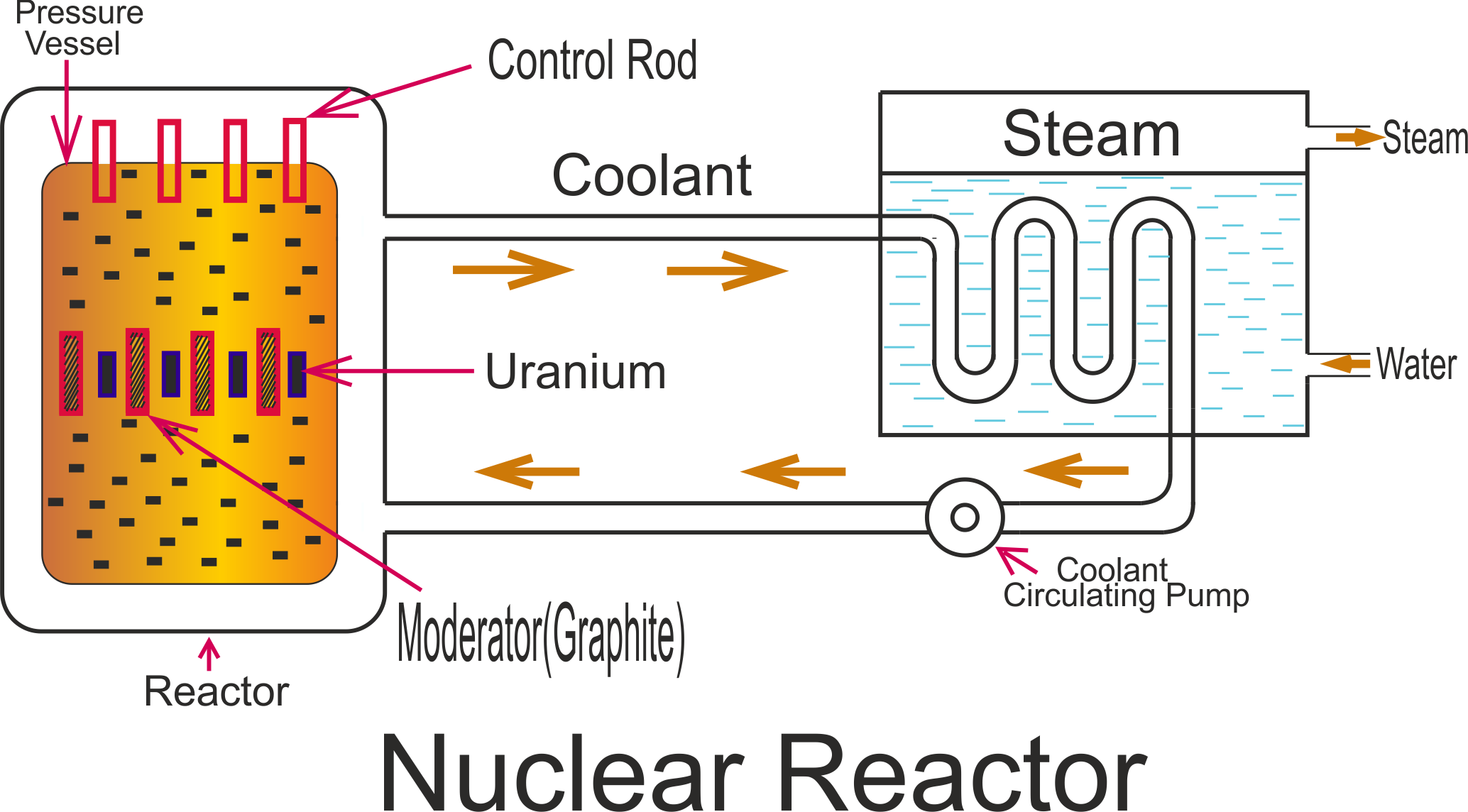

Nuclear Reactor Diagram And Functions Nuclear Reactor

Nuclear Reactor Diagram And Functions Nuclear Reactor

Nuclear Reactor Diagram And Functions Nuclear Reactor

Nuclear Reactor Diagram And Functions Nuclear Reactor

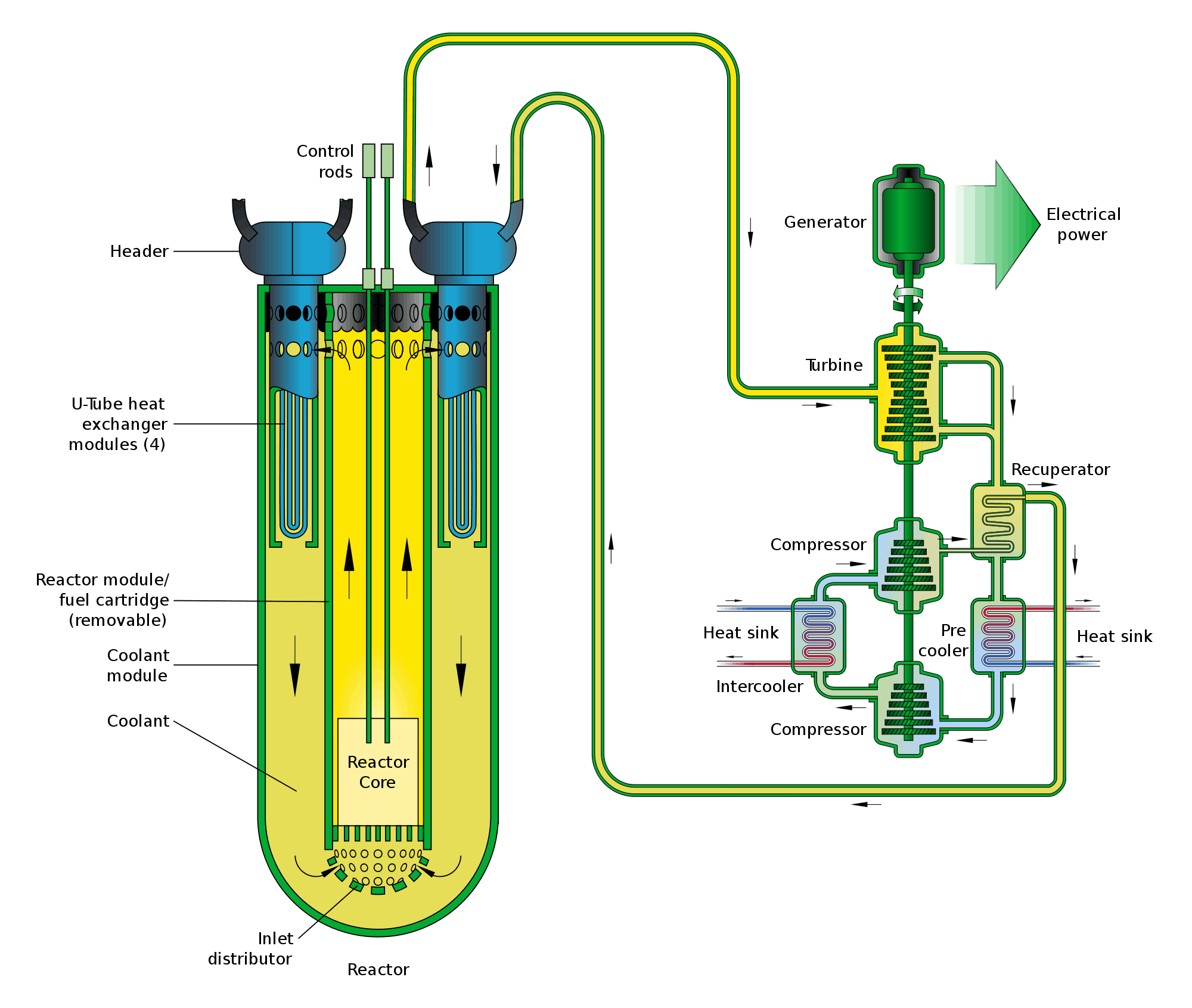

Fast Neutron Reactor | Definition & Components | nuclear-powercom

Fast Neutron Reactor | Definition & Components | nuclear-powercom

Nuclear Reactor Diagram

Nuclear Reactor Diagram

Nuclear reactor - Liquid-metal reactors | Britannica

Nuclear reactor - Liquid-metal reactors | Britannica

Nuclear Power Plant Reactor Diagram Nuclear Reactor Schemati

Nuclear Power Plant Reactor Diagram Nuclear Reactor Schemati

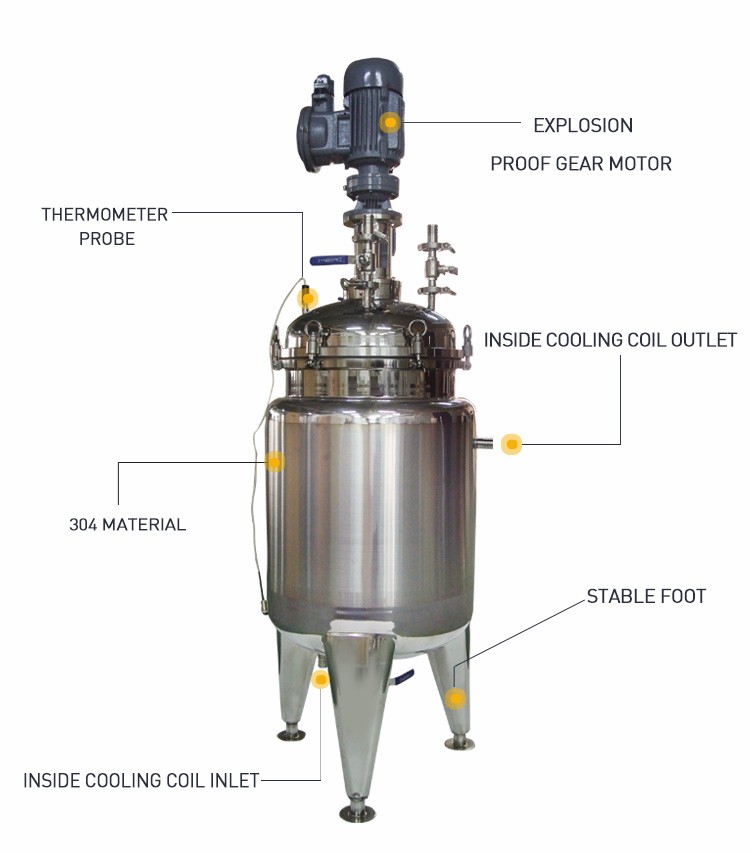

Advantages Of Stainless Steel Chemical Reactor And Working Principle

Advantages Of Stainless Steel Chemical Reactor And Working Principle

How Does a Nuclear Reactor Work? A Closer Look at the Working Principle

How Does a Nuclear Reactor Work? A Closer Look at the Working Principle

Reactor Core Nuclear Power Plant Diagram Reactor Pressurized

Reactor Core Nuclear Power Plant Diagram Reactor Pressurized

Transmutation and Nuclear Energy | Chemistry

Transmutation and Nuclear Energy | Chemistry

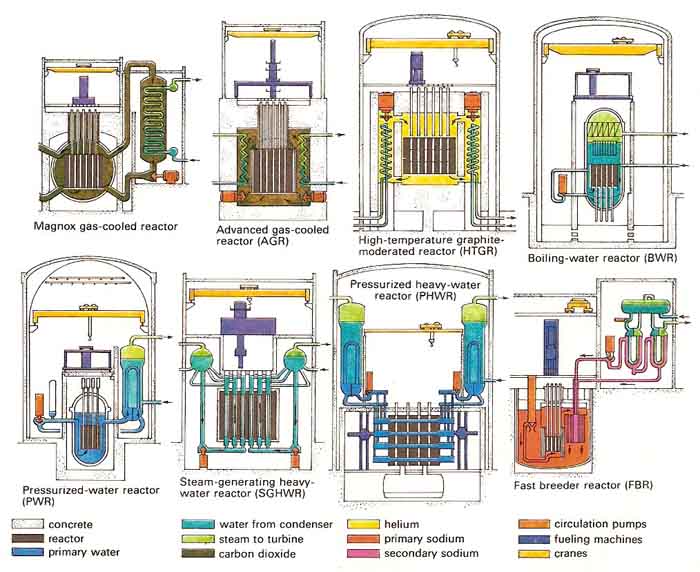

Nuclear Reactor Designs

Nuclear Reactor Designs