Far more than colorful lines and simple geometric shapes that help mitigate hazards, floor marking is a useful organizational tool that can prove invaluable for.

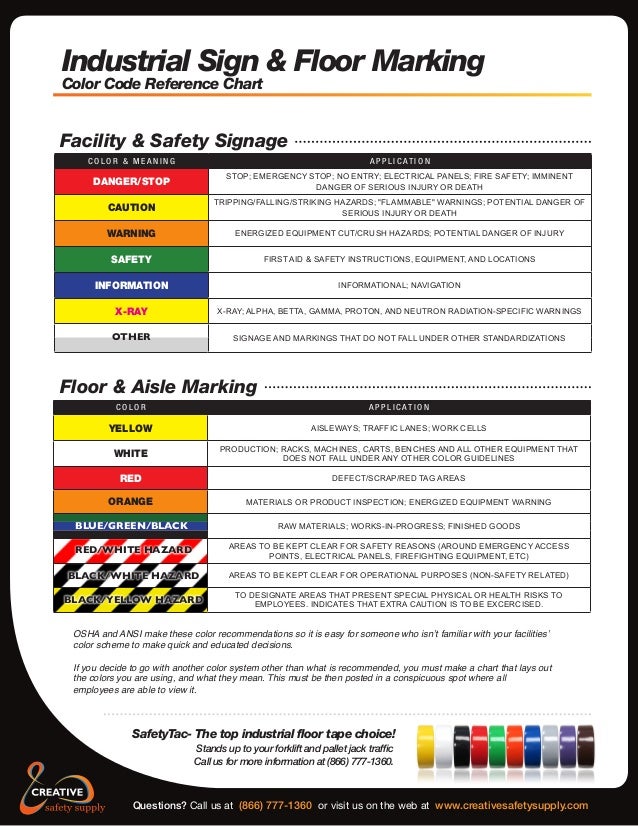

Standard floor marking colors. In addition to giving guidelines on where floor markings should be used, osha often has information about what color the floor markings. Permanent markings should be used in aisles and passage ways and should be a clearly visible color. The color standards have been largely established by osha in their standard cfr 1910.144, which is titled “safety color code for marking physical hazards.” while this section.

First off, osha standards state that aisle markings must clearly define the actual aisle space. With the right colors in the right places, you can easily keep workers on the right path and identify equipment, storage areas, hazardous areas, forklift. These purposes are outlined in the osha standard 29 cfr 1910.144 — the safety color code for marking physical hazards.

Covers main functions of a floor tape color code. To standardize floor markings and enhance 5s initiatives, companies can use the 5s floor marking color guidelines. Improve safety, operate at greater efficiency, and adhere to regulations, including osha.

When creating a floor marking strategy for your facility, there are many things to. Floor marking color standards guide. Color coordinating your facility floors, a new standard.

Recommend what colors to use when marking floors. With the right colors in the right places, you can easily keep workers on the right path and identify equipment, storage areas, hazardous areas, forklift. Osha color requirements for warehouse floor marking.

(osha standard 1910.22) one of the top osha violations is “walking/work surface violations” with an average fine of $1,632 per individual violation. Get catalog | get free samples. However, these specifications are extremely.

.jpg?w=600)