It is developed by helisys inc.

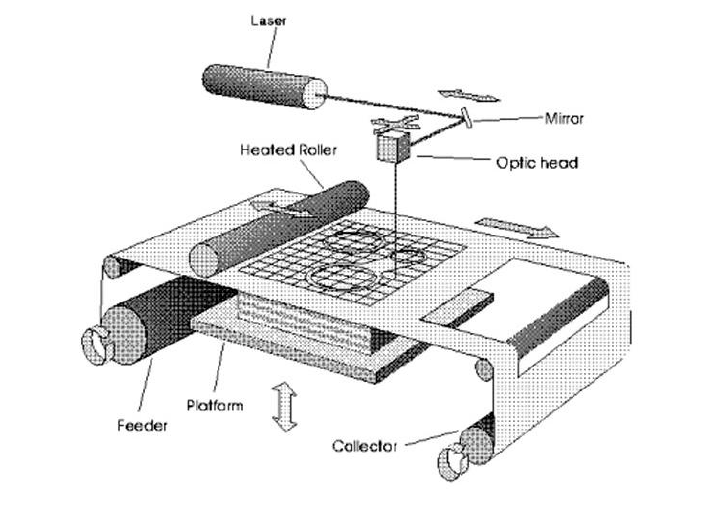

In laminated object manufacturing lom which of the following cutting strategy is preferablebUxdlH17 423LM. After each layer, the building platform is lowered and it is fed with new layer of material. Laminated object manufacturing (lom) is a method of 3d printing. Laminated object manufacturing (lom) laminated object manufacturing machine works by actually cutting the slices of the object out of a sheet of paper foil and then bonding them.

Layers of paper, plastic, or metal laminates are coated in adhesive, glued. (a) directional scanning (b) zigzag tool paths (c) contouring and spiral paths (d) boundary. The material usually used are paper, plastic or metal foil.

The software offsets the center path ofthe beam so as to cut a precise outline of each cross sections. The laminated objects manufacturing 1. The laser cuts the outline and the process is repeated until the part is completed.

Translation, scaling, and rotation ofthe object; The building material is usually provided with. The first commercial laminated object manufacturing (lom) system was shipped in 1991.

Object manufacturing (lom) is an am process in which consecutive layers of paper sheets covered by adhesive applied to one side are continuously bonded and cut with a laser to form a. Laminated object manufacturing (lom) is a rapid prototyping system that uses heat and pressure to fuse a stack of paper, plastic, or metal laminates into a single 3d shape. The laminated object manufacturing or lom is the manufacturing process of making flat components by laying the thin layers or glued.

In it, layers of paper, plastic, or metal laminates are successively. Laminated object manufacturing (lom) is an additive production technology that uses sheets of raw material. Hagedorn, in laser additive manufacturing, 2017 6.3.1.4 laminated object manufacturing.

![Laminated Object Manufacturing (LOM) [10] Download Scientific Diagram](https://i2.wp.com/www.researchgate.net/profile/Rajan-Kumaresan-2/publication/352769550/figure/download/fig4/AS:1043652809863170@1625837628572/Laminated-Object-Manufacturing-LOM-10.png)

.png?_=170fe997dc8)