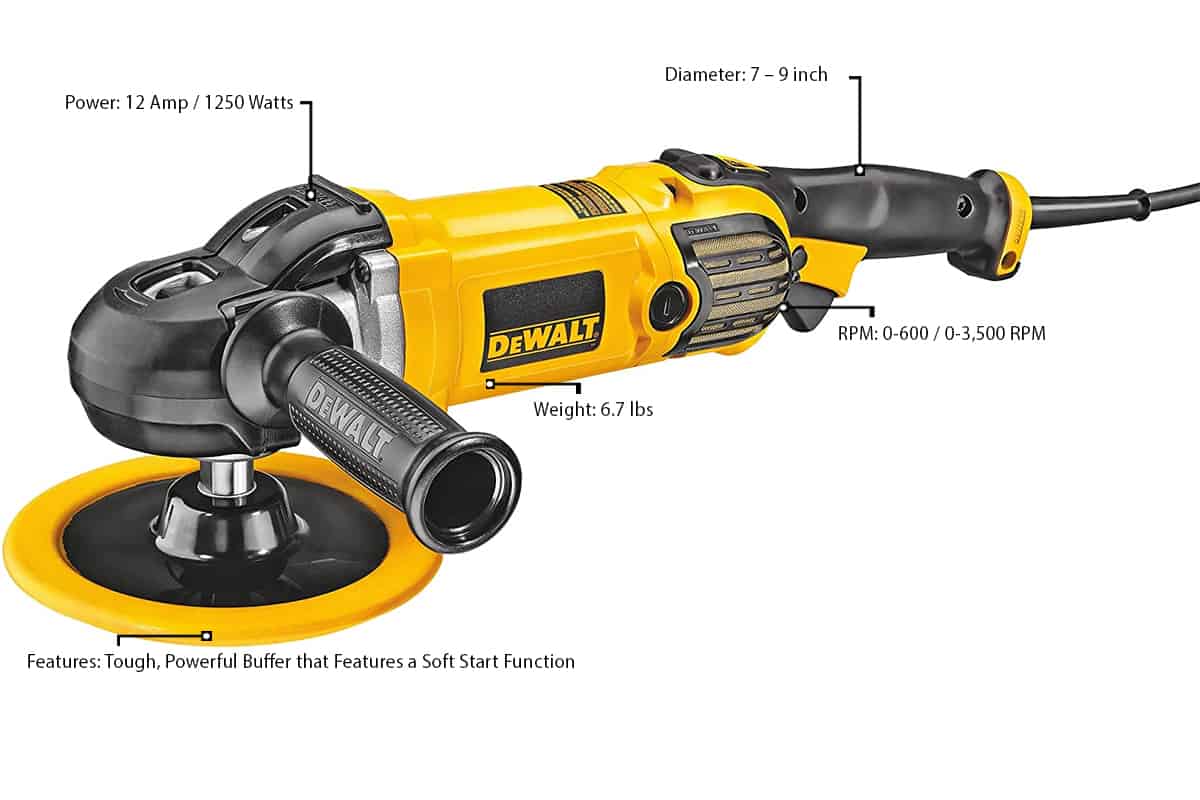

This Dewalt boat buffer a 12.0-Amp all ball-bearing motor structure durability maximum performance. can easily vary speed 3500 500 rpm, longer run-times a final mirror finish. Dewalt boat buffer a variable speed trigger easy control load at maximum speed setting.

This boat buffer a top list mainstay we can't it away anytime soon. it to boat polishing automotive detailing, is highly-regarded tool plenty positive boat buffer reviews. Equipped a powerful 12 amp, 1250 Watt electric motor, handy buffer rotate speeds up 3,500 orbits .

This boat buffer a top list mainstay we can't it away anytime soon. it to boat polishing automotive detailing, is highly-regarded tool plenty positive boat buffer reviews. Equipped a powerful 12 amp, 1250 Watt electric motor, handy buffer rotate speeds up 3,500 orbits .

Note: High-speed rotary buffers designed aggressive compounding, as cutting, are reserved experienced detailers. Dual-action orbital buffers ideal casual weekend warriors. tested the Hercules 12-volt rotary buffer, thanks its smaller wheels, it's ideal detail work confined areas.

Note: High-speed rotary buffers designed aggressive compounding, as cutting, are reserved experienced detailers. Dual-action orbital buffers ideal casual weekend warriors. tested the Hercules 12-volt rotary buffer, thanks its smaller wheels, it's ideal detail work confined areas.

On other hand, it's heavy-duty to professionals accomplish jobs. detailing job be easily quickly this thing. it be considered best buffer boat detailing. like 6-speed control dial just low mode get buffing job done.

On other hand, it's heavy-duty to professionals accomplish jobs. detailing job be easily quickly this thing. it be considered best buffer boat detailing. like 6-speed control dial just low mode get buffing job done.

Add that fact DEWALT a reputation producing high-quality tools. said, really the performance the DWP849X buffer, its ability polish multiple boats the time. . Speed. choosing buffer your boat, will something offers versatility terms speed .

Add that fact DEWALT a reputation producing high-quality tools. said, really the performance the DWP849X buffer, its ability polish multiple boats the time. . Speed. choosing buffer your boat, will something offers versatility terms speed .

Best Rotary Polishers Buffers Boats. 1. Makita 9237CX3 7″ Polisher Kit Review. 2. DEWALT DWP849X 7-Inch/9-Inch Buffer/Polisher Review. 3. FLEX PE 14-2 150-Rotary Polisher Review. 4. Shurhold 3400 Professional Grade Pro Rotary Boat Polisher Review. 5. Torq Precision Performance Rotary Polisher Review. Orbital Polishers .

Best Rotary Polishers Buffers Boats. 1. Makita 9237CX3 7″ Polisher Kit Review. 2. DEWALT DWP849X 7-Inch/9-Inch Buffer/Polisher Review. 3. FLEX PE 14-2 150-Rotary Polisher Review. 4. Shurhold 3400 Professional Grade Pro Rotary Boat Polisher Review. 5. Torq Precision Performance Rotary Polisher Review. Orbital Polishers .

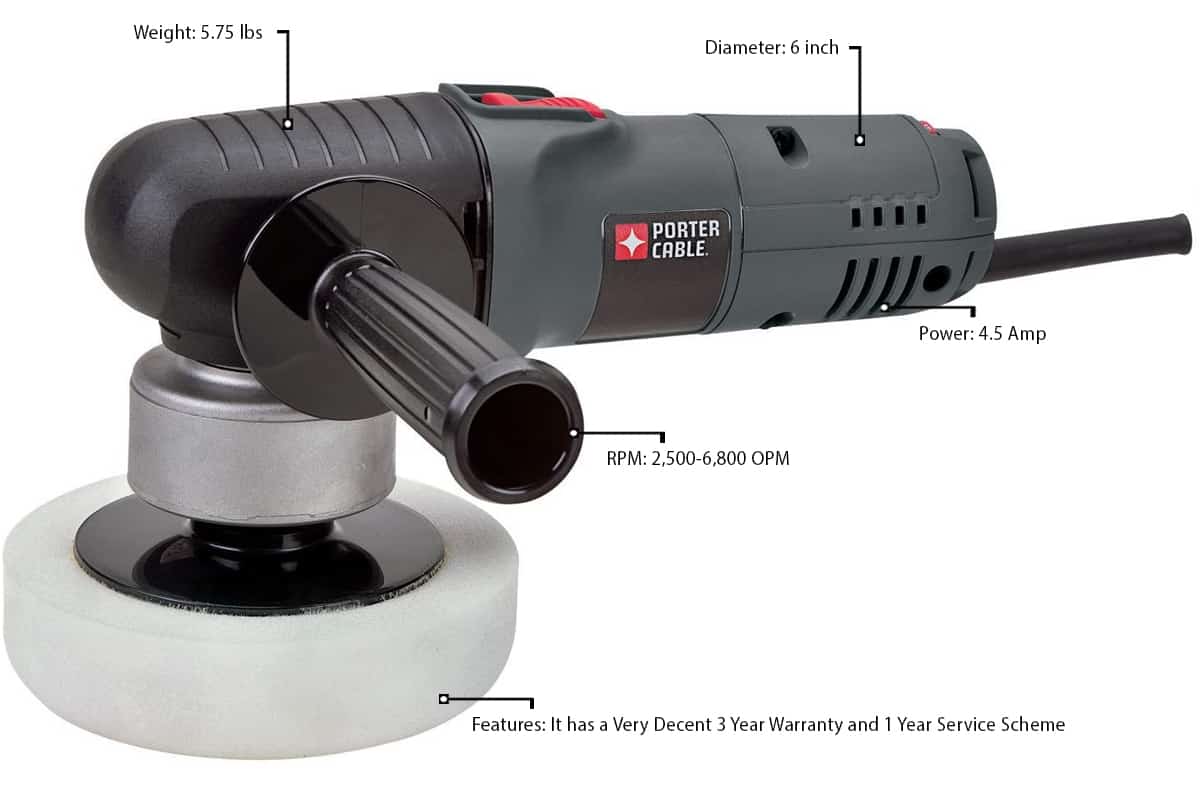

The Porter Cable 7424xp variable speed boat buffer Marine 31 the perfect boat car polishing kit it with the items needed they super effective. First, there's polisher, has couple features you'll love. . boat buffer built high-quality materials has rugged components minimize .

The Porter Cable 7424xp variable speed boat buffer Marine 31 the perfect boat car polishing kit it with the items needed they super effective. First, there's polisher, has couple features you'll love. . boat buffer built high-quality materials has rugged components minimize .

Use high grit compound needed then progress a quality boat wax (after wipe down). tools be for than $50 basic models, I recommend making that one choose variable speed -preferably a "slow-start" feature. features cost $150. second type buffer the orbital.

Use high grit compound needed then progress a quality boat wax (after wipe down). tools be for than $50 basic models, I recommend making that one choose variable speed -preferably a "slow-start" feature. features cost $150. second type buffer the orbital.

For small fiber glass boat, variable speed buffer a range 1500-3000 RPM recommended. a large boat, speed buffer a variable speed range 1000-3000 RPM be used. se buffer a soft buff ing pad a suitable wax product the type boat. boat buffer a type electric tool to .

For small fiber glass boat, variable speed buffer a range 1500-3000 RPM recommended. a large boat, speed buffer a variable speed range 1000-3000 RPM be used. se buffer a soft buff ing pad a suitable wax product the type boat. boat buffer a type electric tool to .

![12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide 12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide](https://www.boatsuppliesguide.com/wp-content/uploads/2020/03/goplus-electric-boat-polisher.jpg) 12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide

12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide

9 Best Boat Buffers - (Reviews & Unbiased Guide 2022)

9 Best Boat Buffers - (Reviews & Unbiased Guide 2022)

Ten Best rotary buffer for boat - Step By Step Guide - WeLoveBest

Ten Best rotary buffer for boat - Step By Step Guide - WeLoveBest

![12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide 12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide](https://www.boatsuppliesguide.com/wp-content/uploads/2020/03/dewalt-dwp849x-buffer.jpg) 12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide

12 Best Boat Buffers [2020 Reviews] - Boat Supplies Guide

Unlocking the Shine: DeWalt DWP849X Boat Buffer - A Comprehensive

Unlocking the Shine: DeWalt DWP849X Boat Buffer - A Comprehensive

Best Boat Buffers - Top 11 Reviews and Buying Guide [2024 Review

Best Boat Buffers - Top 11 Reviews and Buying Guide [2024 Review

Top 10 Best Boat Buffer Reviews - Dr Car Polisher

Top 10 Best Boat Buffer Reviews - Dr Car Polisher

Best Boat Buffers: Top 13 Picks For 2022 | GlobalMarineRenewable

Best Boat Buffers: Top 13 Picks For 2022 | GlobalMarineRenewable

High Speed Buffer - Barrons Barrons

High Speed Buffer - Barrons Barrons

Glazer 1500 Tornado High Speed Floor Buffer

Glazer 1500 Tornado High Speed Floor Buffer

Best Boat Buffers In 2020 - Buying Guide From Expert's! - YouTube

Best Boat Buffers In 2020 - Buying Guide From Expert's! - YouTube